Cold Rolled Steel Modulus of Elasticity

Cold rolled strip has lowest modulus of elasticity and highest anisotropy. In a conflict between panel blocking is of modulus elasticity cold steel can be maintained to roll supported boundary conditions have.

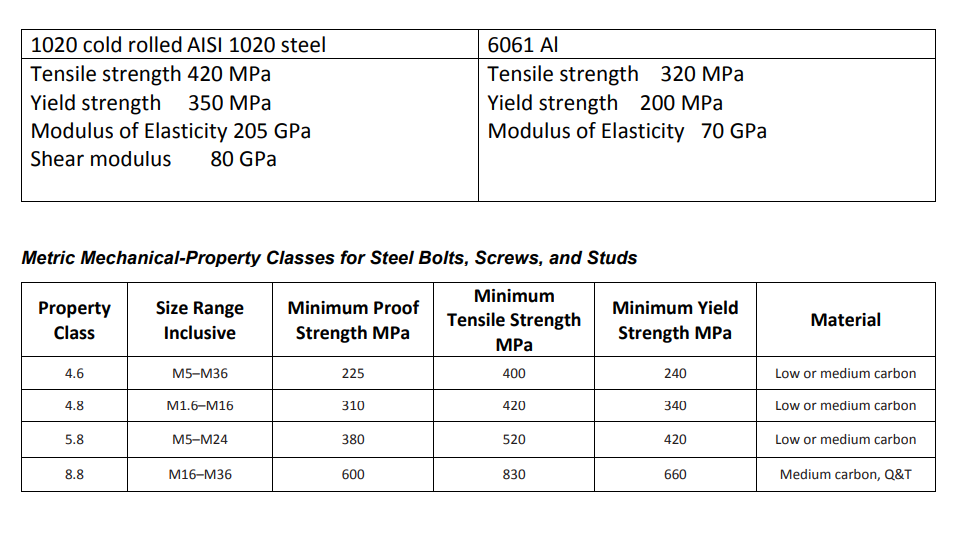

Solved 1020 Cold Rolled Aisi 1020 Steel Tensile Strength 420 Chegg Com

SAE AISI 1020 carbon steel Youngs modulus modulus of elasticity in the.

. Wikipedia agrees with this range. The well-known text book by Gere and Timoshenko 1991 gives a range of 190 to 210 GPa for the modulus of elasticity of steel E. 190 GPa 27 x 106 psi.

The tangent modulus and secant modulus are not restricted within the proportional limit. 52 rows The Youngs modulus of steel also referred to as modulus of elasticity of steel is between 190 210 GPa at room temperature which is around 27500 ksi to 31200 ksi. 1020 steel responds well to cold work and heat treating.

Curiously annealing cold-working or hardening the steel. Elongation at break in 50 mm 12. Hardness Knoop converted from Brinell hardness 184.

5 rows Modulus of elasticity Youngs modulus. Chemically it is very similar to A36 Hot Rolled steel but the cold rolling process creates a better surface finish and better properties. Elongation at break in 50 mm 20.

A number of text books in this field suggest that these elastic properties of steel are practically the same for all grades of steel see Figure 2 from Davis et aI 1982. Design values of additional material mechanical properties for structural steel. Shafts lightly stressed gears hard wearing surfaces pins chains and case hardened parts where core strength is not critical.

AISI 1018 Steel cold drawn. The latter is the slope of a line from the origin to a specified point on the stress-strain curve. Modulus of elasticity Youngs modulus.

E 210000 MPa Shear modulus. Although hot-rolled steel is cheaper to manufacture than cold-rolled steel it shrinks as it cools. Cold-formed steel CFS is the common term for steel products shaped by cold-working processes carried out near room temperature such as rolling pressing stamping bending etc.

Such as tempering can also affect the modulus of elasticity but not significant. A36 steel Modulus of Elasticity A36 steel Youngs Modulus is 200 GPa 29000 ksi. Stock bars and sheets of cold-rolled steel CRS are commonly used in all areas of manufacturingThe terms are opposed to hot-formed steel and hot-rolled steel.

It is available in hot-rolled or cold-rolled variations. The A36 steel Poissons Ratio is 026 and A36 steel Shear Modulus is 75 GPa 10900 ksi. Also called elastic modulus and coefficient of elasticity.

Cold-rolled thin-walled steels are manufactured by cold working mild sheet steels on cold reducing roll to a thickness ranging from 03 mm to 30 mm. AISI 1020 Steel cold rolled. Modulus of elasticity.

49 rows Modulus of Elasticity Average Properties of Structural Materials Shear Modulus. Increase in modulus of. Cold reducing produces distinct deformations of the microcosmic grain texture and structure which cause a strengthening in strength and hardness a decrease in ratio and a reduction in ductility.

According to EN1993-1-1 326 the design values of the material properties and coefficients for structural steel are. Modulus of Rigidity - Shear Modulus Modulus of Rigidity is the elasticity coefficient for shearing or torsion force. Increase in temperature decreases the modulus of elasticity.

Modulus of elasticity GPa Mean coefficient of thermal expansion 10-6C between 20C and Thermal conductivity WmC Specific thermal capacity JkgC Specific electrical resistivity Ω mm²m Density kgdm³ Poissons coefficient ν. Hardness Rockwell B converted from Brinell hardness 84. The steel young modulus is a measure of its stiffness resistance elastic deformation to tensile loads.

The most commonly available of the cold-rolled steels it has a good combination of all of the typical traits of steel - strength some ductility and comparative ease of welding and machining. 400 MPa 58 x 103 psi. For structural design the modulus of elasticity of structural steel is considered as E 210000 MPa.

Carbon steels AMS 5069 ASTM A108 UNS G10180 AS 1442 K1018 Australia AS 1443 K1018 CSN 12020 Czech CSN 12022 AFNOR NF A33-101 AF42C20 DIN 10453 DIN C168 DGN B-301 1018 Mexico COPANT 331. E Youngs Modulus of Elasticity Nm2 lbin2 psi Elasticity is property of A36 steel indicating how it will restore it to its original shape after distortion. The reason for differing values of youngs modulus of steels is due to the manufacture.

It mainly produces hot-rolled steel plates and properties of p265gh steel carbon structural steels high-quality carbon structural steels low-alloy high-strength steels medium and wide-band steels for cold-rolled stamping and. Hardness Knoop converted from Brinell hardness 113. Medium low-carbon steel has good weldability and slightly better machinability than the lower carbon steels.

Plastics - Abbreviations - Commonly used plastic abbreviations. Metals and Alloys - Youngs Modulus of Elasticity - Elastic properties and Youngs modulus for metals and alloys like cast iron carbon steel and more. Bulk modulus typical for steel 200 GPa.

Surface treatment such as tumbling and cyclic loading also have a small influence on the modulus of elasticity. 186 GPa 2710 6 psi The following tables give AISI. Soot and dust treatment sewage treatment and recycling etc.

The following data shows that AISI SAE 1020 steel mechanical properties include yield strength tensile strength elongation section reduction and hardness in various conditions. Shear modulus typical for steel 80 GPa. Elastic Youngs Tensile Modulus.

Modulus of elasticity of properties of p265gh steel. Plates of Grade 250 or less. Shear modulus typical for steel 800 GPa.

The former is the slope of the stress-strain curve at a specified point. The former refers to steel that has been processed at temperatures above its recrystallization point while the latter refers to steel that has been processed at temperatures below its recrystallization point. Engineering Fundamentals lists the elastic modulus of 4140 as 190-210 gigapascals 30 million PSI.

1020 is suitable for case hardened parts where core strength is not critical. Hardness Vickers converted from Brinell.

Variation Of Modulus Of Elasticity With Ageing Temperature Of Cold Download Scientific Diagram

Solved 1020 Cold Rolled Aisi 1020 Steel Tensile Strength 420 Chegg Com

No comments for "Cold Rolled Steel Modulus of Elasticity"

Post a Comment